High strength copper alloy is cast on the surface of 45# or GCr15 as the basic material of the bearing. This manufacturing process makes the copper and steel bonding surface achieve complete metallurgical bonding, which reduces the material cost and improves the bearing capacity. However, inlaying solid lubricant on the working face according to the working conditions greatly reduces the friction coefficient of the bearing and achieves the purpose of self-lubrication.

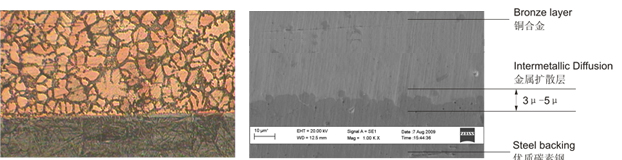

It can be seen from the metallographic diagram that there is mutual diffusion between the steel and copper alloy in the critical region, and the diffusion layer generated in the casting process is about 3μ-5μbetween the two materials to achieve complete metallurgical bonding and form a good bonding strength, which in any case exceeds the mechanical strength of the copper alloy itself.

The diffusion of steel and copper between each other provides excellent mechanical properties of this material, while the heat generated during the operation of the bearing can be transferred in time. The thin-walled copper alloy layer allows the double-layer material to have a similar coefficient of thermal expansion, so the 650GT material can be heat-treated as needed after casting, which means that this new material can ensure high accuracy and mechanical fit during use.

It combines the wear resistance of copper alloy with the high mechanical strength of steel.

· Different copper alloys can be cast according to the requirements of working conditions, including lead-copper alloys with low friction properties;

· Due to the different friction coefficients of the inner and outer layer materials, the bearing can be prevented from moving and rotating under high load and low speed conditions;

· It can be covered or inlaid with solid lubricant on the working surface as needed to achieve self-lubrication;

· Compared with pure copper sleeve, it has more cost advantages and saves resources;

· Can carry out post-processing, such as heat treatment of steel matrix, alloy layer machining, etc.;

· One or more layers of copper alloy casting can be performed on different or complex surfaces according to the design needs;

· Similar to the traditional copper sleeve in the use of characteristics, can be suitable for different temperatures under different lubrication conditions;

· Compared with pure copper sleeve, it has better mechanical bearing performance, especially impact strength

| Material composition and properties table | ||||

| Material grade | 450GT 400GT | 450GT1 400GT1 | 450GT3 400GT3 | 450GT5 400GT5 |

| Copper alloy composition | CuZn25Al5Mn4Fe3 | CuSn5Pb5Zn5 | CuSn12 | CuZn25Al5Mn4Fe3 |

| Alloy layer hardness HB | >210 | >70 | >95 | >250 |

| Bonding strength of alloy layer Mpa | >150 | >100 | >100 | >150 |

| Maximum static load Mpa | 250 | 150 | 150 | 250 |

| Maximum dynamic load Mpa | 100 | 60 | 70 | 120 |

| Maximum linear velocity (dry) m/min | 15 | 10 | 10 | 15 |

| Maximum PV valueN/mm2*m/min | 200 | 60 | 80 | 200 |

| Coefficient of thermal expansion 10-5/K | 1.2x10-5/℃ | 1.2x10-5/℃ | 1.2x10-5/℃ | 1.2x10-5/℃ |

| Service temperature℃ | -40~+300 | -40~+400 | -40~+400 | -40~+150 |

| Permanent compressive deformation 300N/mm2 | <0.01mm | <0.05mm | <0.05mm | <0.005mm |